Building sites become "low-carbon gardens" to create "good scenery" around residents.

Science and Technology Daily reporter Zhang Wei correspondent Wu Qi

On April 20th, on the occasion of the 56th World Earth Day, a construction site in Wuxi City, Jiangsu Province opened its doors to popularize the technological achievements of low-carbon construction for the citizens.

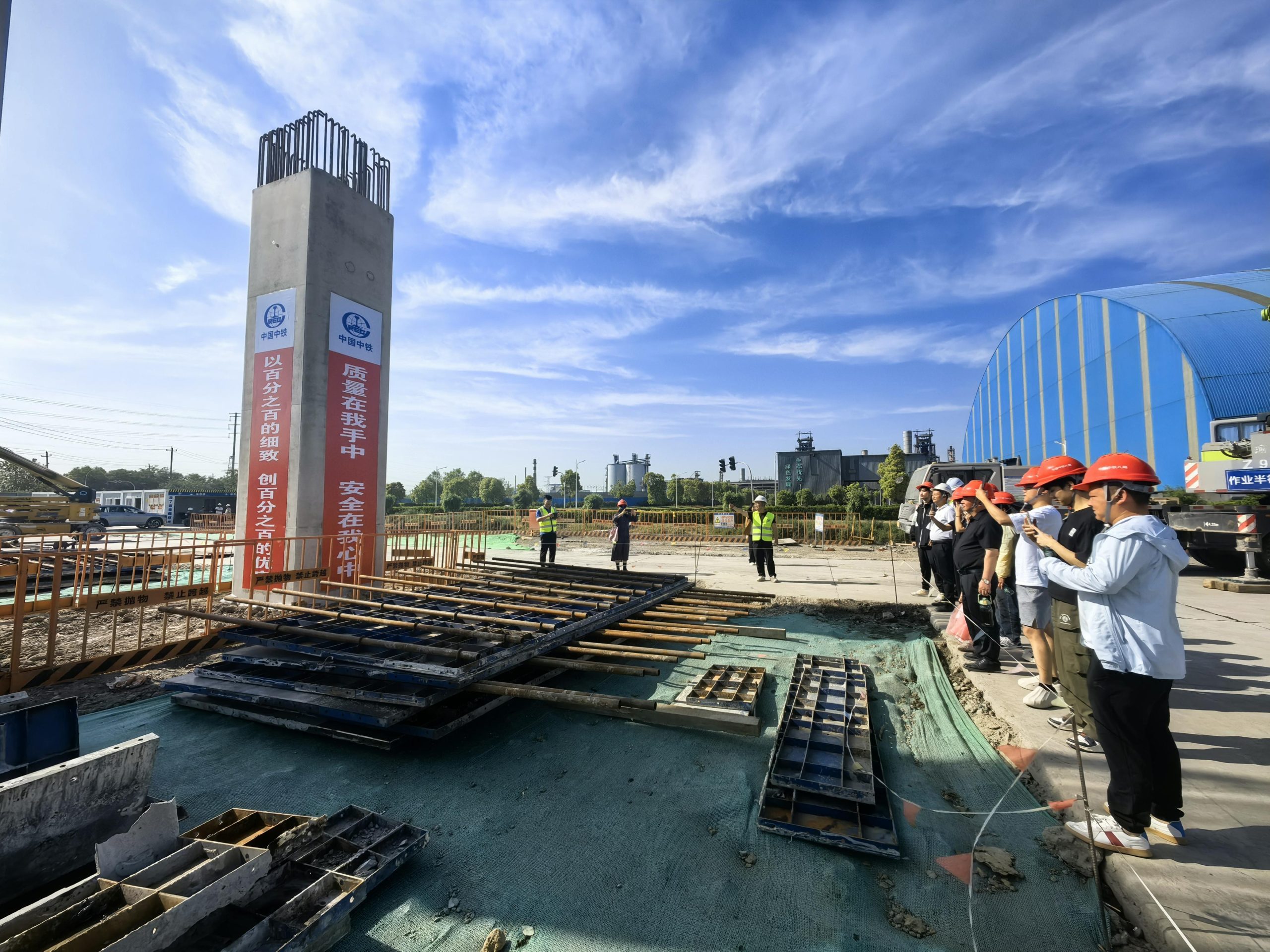

"This is the pier of the bridge, just like the’ leg’ of the bridge. Under our feet is an integrated ladder cage and an outer frame platform used for pier construction. Different from other construction sites, these facade platforms are composed of modularity, just like building blocks, which can be assembled by themselves according to production needs, which reduces the steel loss by 25% compared with traditional scaffolding, which is both environmentally friendly and efficient. " The technician of Zhenghe Avenue Project of China Railway Eighth Bureau, the construction party, said.

"In the past, we were faced with all units in the industry. This time, opening the door to the general public is not only a test of the project construction level, but also enhances the communication between enterprises and society." At the activity site, Yang Zhiqiang was introducing the energy-saving and emission-reduction technologies, green construction techniques and the results of resource recycling applied in the project construction to the surrounding residents who came to visit.

Walking into the construction site, there was no smoke and dust generated by mechanical exhaust, and rows of piers rose from the ground to take shape. The standardized and intelligent construction scene made the visiting residents stop to take pictures. Yang Zhiqiang said: "This is an automatic dust monitoring system, which can be intelligently linked with the enclosure spray device. When the values of PM2.5 and PM10 on site exceed the standard, the system will automatically trigger the spray to let the dust’ fall to the ground’, thus realizing dynamic control." Not only do environmental protection in the enclosure be well implemented, but the project department also upgraded the automatic car washing device at the entrance and exit of the construction site. The sewage after precipitation and filtration can be used for secondary washing of vehicles and sprinkling water on roads to suppress dust. Through recycling, the construction water can be saved by 2000 tons on site every year.

From the construction point of view, it is not an easy task to achieve low carbon. Since entering the site, the Zhenghe Avenue project team of China Railway Eighth Bureau has insisted on integrating the concept of "zero carbon" into the construction details, and introduced a number of environmental protection measures in view of the high energy consumption and high pollution points in traditional construction. Through the linkage of mechanization+intelligence+greening, the project construction has started at full speed.

According to Jiang Yong, the person in charge of the project, the idea of reducing carbon in the project department starts from "replacement" and "reduction". For example, after the construction wastes are classified, hard wastes such as concrete blocks and masonry are broken into construction access roads, steel scraps are recycled into safety guardrails, and wood scraps are processed into temporary facility templates, with a comprehensive utilization rate of over 60%; The temporary facilities on the site are all made of reusable materials, and 70% of the components can be reused after the project. In addition, the introduction of solar outdoor lighting in the living quarters of the construction site can save about 12,000 kWh of electricity every year.

"It’s really not the same as the imagined construction site. I used to worry that the production of construction sites nearby would affect my life. Today, I see that there are so many scientific and environmental protection measures to ensure it, and my heart is much more practical!" Ms. Zhang, a surrounding resident who participated in the event, said with emotion. As a key project in Huishan District, Wuxi City, the construction of the bridge substructure of the project is currently in full swing. Talking about the follow-up construction plan, Jiang Yong said that in the future, the project department will actively apply AI technology to help in resource allocation and further realize the carbon reduction goal of the project construction.

(Photo courtesy of the interviewee)